Mooney viscosity—PC type traders|mooney scorch value : store A Mooney viscometer is an instrument used for measuring the Mooney viscosity of rubbers. Invented by Melvin Mooney, it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle and the mooney viscosity is calculated from the torque on the spindle. Resultado da GWA Search Panel. Light/Dark Mode: Subreddit: Included Tags. Excluded Tags. Posters. Exclude Flair Script Fills Improvisations Ramblefaps Script Offers Requests. Sort by. Time Range. Search .

{plog:ftitle_list}

Resultado da 2 de set. de 2022 · Free For All | 3 Girls 1 Kitchen | S3E8. Sponsors: HelloFresh: www.hellofresh.com/3g1k Babbel: www.babbel.com/3g1k BetterHelp: .

mooney viscosity examples

Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the compound’s viscosity. The appropriate standards associated with this test are IS0 289, ASTM D 1646, and DIN 53523-3. The units of measurement are known as Mooney units.

mooney viscosity

Materials. Robert Flitney, in Seals and Sealing Handbook (Sixth Edition), 2014. .A Mooney viscometer is an instrument used for measuring the Mooney viscosity of rubbers. Invented by Melvin Mooney, it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle and the mooney viscosity is calculated from the torque on the spindle.

Mooney Viscometer controlled by Personal Computer. The mooney viscometer is a shearing-disc viscometer, which permits to measure the Mooney viscosity, Pre-curing (scorch) and Stress .The Mooney Viscometer Mk III measures and records the viscosity of natural, synthetic or compounded rubber. Conforming to international standards, the .Mooney viscosity measurements have been found helpful in estimating the processing characteristics of rubbers. They must be supplemented by other types of tests, however, .

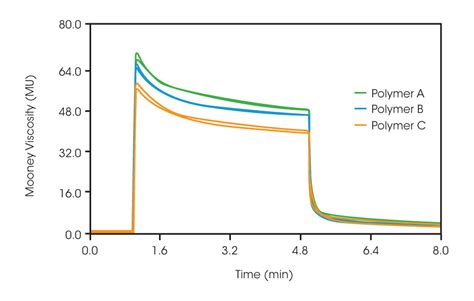

The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is .

it is most essential that precautions be taken in caring for and adjust-ing Mooney viscometers with respect to the following five items: 669008—45 1. (1) The machine must be clean; .Mooney viscometers are mainly used to test characteristics of raw materials before mixing - to verify that they meet required standards for the formulation in which they are to be used. To .

mooney scorch value

o'brien compression test

This article identifies and describes factors that affect Mooney viscosity test results; defines parameters that eliminate discrepancies in data generated by different Mooney .

To that end, we investigated Mooney torque relaxation. The Mooney viscometer is an inexpensive instrument (cost and maintenance) that is easy to use and, above all, available in the great majority of factories producing natural rubber. The measurement of NR Mooney viscosity is governed by international standard ISO 289.

The Mooney Viscosity of rubber is a specific measurement of the viscosity of unvulcanised rubber performed on a Mooney Viscometer. The measurement uses its own unique empirical scale, Mooney Units, that is difficult to map to alternative measurement of viscosity that use standard units. . Instrument/Equipment: Mooney Viscometer Test Type .5. The maximum test time: Mooney: 10min; Scorch: 120min (modification time during testing) 6. Mooney value of measuring range: 0 to 200 7. Mooney value resolution: 0.1 Mooney value 8. Mooney value measurement accuracy: ± 0.5 Mooney value 9. Calibrate accuracy: 100±0.5 Mooney value 10. Rotor speed: 2 ± 0.02r/min 11.

Mooney Viscosity. This test is the most commonly used test method for characterizing uncured rubber materials and polymers. The sample material is heated for a predetermined period of time, then sheared by an embedded rotor at a constant rate. We then record the Mooney Viscosity and automatically calculate data at defined times and viscosity .Part 1: Determination of Mooney viscosity. Buy. Follow. Table of contents. Foreword. 1 Scope. 2 Normative references. 3 Principle. 4 Apparatus. 4.1 Typical shearing-disc viscometer. 4.2 Dies. 4.3 Rotor. 4.4 Heating device. 4.5 Temperature-measurement system. 4.6 Die-closure system. 4.7 Torque-measurement device and calibration of the device.

Abstract The direct near‐infrared spectroscopic reflectance measurements of prevulcanized natural rubber (brown crepe) was employed for determination of its Mooney viscosity. NIR reflectance spectra were obtained for a total of 100 samples whose Mooney viscosity (VM in the range 68–95 units) have been determined by the standard reference .literature (Sherman, 1983) is the Mooney's equation (1951). Using functional analysis, Mooney derived the following equation to describe the relative viscosity/concentration behavior of rigid, spherical particles: T/, =exp[2.54>/(I-aM4>)) (1) where T/, is the relative viscosity, 4> is the volume fraction of the solids, and aM is It is interesting that the Mooney viscosity for one of the `bad' lots was very close to the Mooney viscosity for the `good' lot (ML1+4 of 93 vs 94). Table 11 gives a description of these three lots. Fig. 31 shows very good separation of the `good' vs the `bad' lots of natural rubber when comparing the uncured tan δ at high strain test conditions.

MOONEY VISCOMETER MOONEYCHECK DRIVE Best Application: MOONEY VISCOMETER – MOONEYCHECK DRIVE The Mooney Viscometer – Mooneycheck Drive operates as a Mooney Viscometer, offering the capability to measure Mooney viscosity, Pre-curing (scorch), and Stress Relaxation Characteristics in both uncompounded and compounded rubbers.Get Price Quote. Rotor speed : 2.0 ± 0.02 RPM Temperature : 50 to 200oC It is an instrument consisting of a motor driven disk within a die cavity formed by two dies maintained at specified conditions of temperature and die closure force. It measures the effect of temperature and time on viscosity of rubber or compound.It is a measure of the viscosity more.Certifi cate No. 0395 Certifi cate No. 3088 Technical Specifi cations Design Spec. ISO No. 289/ ASTM D1646 Electrical Single Phase 220/240V 50HZ, 110v 60Hz. Pneumatics Filtered air, 4.2 Kg/cm, (60 Psi) Die Confi guration Standard, large or small rotor Rotor Large or small Rotation Speed 0.21 Radians/sec. (2 rpm.) Calibration Fully automatic Temperature Control 3 .

influence of feed compositions on rubber Mooney viscosity† Ge He, ab Tao Luo,*a Yagu Dang,a Li Zhou,a Yiyang Daia and Xu Ji*a Mooney viscosity is an essential parameter in quality control during the production of nitrile-butadiene rubber (NBR) by emulsion polymerization. A process model that could help understand the influence ofMooney scorch 42, 284 Mooney stress relaxation 46 Mooney tests 37 Mooney viscometer 35, 68, 72 – limitations 51 –For personal use only. variable speed 49 Mooney viscosity 7, 37, 277 Moving Die Rheometer (MDR) 13, 79 Mullins effect 118 – for cured rubber compounds 321 multiple frequency sweeps with increasingMooney viscometers are mainly used to test characteristics of raw materials before mixing - to verify that they meet required standards for the formulation in which they are to be used. To perform a Mooney Viscosity Test, the die cavity temperature is set and allowed to stabilize. Then, a specified volume of the sample material is loaded

Mooney viscometers are mainly used to test characteristics of raw materials before mixing - to verify that they meet required standards for the formulation in which they are to be used. To perform a Mooney Viscosity Test, the die cavity temperature is set and allowed to stabilize. Then, a specified volume of the sample material is loaded

Mooney scorch 42, 284 Mooney stress relaxation 46 Mooney tests 37 Mooney viscometer 35, 68, 72 – limitations 51 –For personal use only. variable speed 49 Mooney viscosity 7, 37, 277 Moving Die Rheometer (MDR) 13, 79 Mullins effect 118 – for cured rubber compounds 321 multiple frequency sweeps with increasing

The Mooney Viscosity of Raw Natural Rubber G.M. BRISTOW* Non-standard Mooney test parameters have been derived for a range of raw natural rubber grades in an attempt to obtain information other than a simple assessment of viscosity. Increasing the pre-heat time to 5 tnin and observing the torque-time relation over 1-4 minSuperior Die Cooling and Temperature Stability – Thanks to low mass dies and proprietary digital temperature control, Premier MV delivers excellent temperature stability and a 45% reduction in die cooling time compared to previous models. Does your viscometer do that? Multi-Speed Measurement – Controls for multiple shear rates to establish power law curve and other shear .

This video breaks down everything you need to know. Feel free to use this as a training resource for understanding the Mooney curve. Here is what you will learn: The fundamental theory of the Mooney Curve; Calculation method for Mooney Unit; Calculation method for Stress Relaxation; Explanation of Mooney Scorch; Uses for the Mooney Viscometer .Mooney viscosity ML()1 +4 100°C, but also by Mooney elasticity (a +1). 1. Introduction Natural rubber is a biopolymer originating in trees. Properties of this biopolymer are influenced by genetics of tree as well as by other factors. Characterization of .Mooney viscometer The sample cavity of the Mooney vis-cometer is shown in Fig. 1. The rotor is embedded in a sample and the torque required to move the rotor at 2 rpm is measured. A typical Mooney viscosity measurement is the ML1+42. This test uses a 1 minute preheat with the motor off and then 4 minutes with the motor on at 2 rpm.

The SMV-301 / 301RT allows the user to measure the Mooney viscosity, scorch time, minimum Mooney viscosity, and other characteristics of rubber in accordance with JIS, ISO, and ASTM test methods. With outstanding temperature recovery characteristics and easy operability, it can also be used for stress relaxation measurements or for tests that .Mooney viscosity ML (1+4) 100°C was obtained. The Mooney viscosity is therefore value of torque (in MU) 5 min from the test beginning. After stopping of rotor (at this 5 min time) the stress relaxation of rubber sample (i.e. decrease of torque values in MU) was measured for next 3 min. Fig. (1). Mooney viscosity and Mooney relaxation for .A Mooney viscometer MV 2000 Mooney Viscometer. A Mooney viscometer or rotating disk viscometer is an instrument used for measuring the Mooney viscosity of rubbers. [1] Invented in the 1930s by Melvin Mooney, [2] it contains a rotating spindle and heated dies, the substance encloses and overflows the spindle and the mooney viscosity is calculated from the torque .We are offering Mooney Viscometers. Mooney Viscometer is controlled by Personal Computer. Mooney Viscometer is a shearing disk viscometer, designed for accurate measurement of viscosity, scorch time and cure rates of the elastomers. The instrument consists of flat, cylindrical disk, driven by a motor to rotate slowly and

The Mooney viscosity of the sample set was measured by the standard method and the values were in the range 65–95 units. The samples were divided in two subsets, one for calibration, containing 70 samples, and the other for external validation, containing the remaining 30 samples. The Mooney viscosity average values and their standard .Overview The MooneyCheck - Drive is a Mooney Viscometer, which permits to measure the Mooney viscosity, Pre-curing (scorch) and Stress Relaxation Characteristics of uncompounded or compounded rubbers In conformity with ISO 289-1, .

Resultado da geisy paula oficial nua. subscribe (365) from: anonymous

Mooney viscosity—PC type traders|mooney scorch value